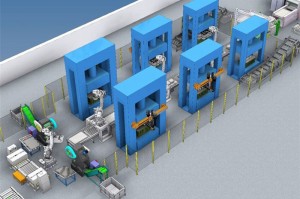

Ultra High Strength Steel (Aluminum) Automatic Cold Cutting /blanking Production Line

Key Features

Hydraulic Presses with Cutting Devices: Equipped with cutting devices, the two hydraulic presses provide accurate and efficient cutting of high-strength steel or aluminum materials. This ensures precise and clean cuts, optimizing the post-processing stage.

Robotic Arms: The three robotic arms integrated into the production line offer flexibility and agility in handling and transferring the materials. They provide repetitive and precise movements, enhancing the overall productivity of the line.

Automatic Loading and Unloading System: The automatic loading and unloading system streamlines the material handling process. It eliminates the need for manual intervention, reducing labor costs and improving overall efficiency.

Reliable Transmission System: The transmission system facilitates the smooth and continuous movement of materials throughout the production line. This ensures reliable and uninterrupted processing, minimizing downtime and maximizing productivity.

Product Benefits

Improved Efficiency: With its automated processes, the Ultra High Strength Steel (Aluminum) Automatic Cold Cutting Production Line significantly improves production efficiency. The elimination of manual labor and the integration of precision cutting devices reduce processing time and increase overall output.

High Precision: The combination of hydraulic presses with cutting devices and robotic arms ensures exceptional precision in the cutting process. This results in accurate and clean cuts, meeting the stringent requirements of high-strength steel or aluminum materials.

Cost-Effective Solution: By automating the post-processing stage, this production line reduces labor costs, minimizes material waste, and enhances production speed. These factors contribute to a cost-effective solution for manufacturers.

Large-Scale Production Capacity: The Ultra High Strength Steel (Aluminum) Automatic Cold Cutting Production Line is designed for continuous, high-volume production. Its automated features, such as the automatic loading and unloading system, enable manufacturers to meet large-scale production demands effortlessly.

Product Applications

Automotive Industry: This production line caters to the automotive industry's needs for post-processing of high-strength steel or aluminum materials. It is ideal for the manufacturing of automotive components, such as chassis and structural parts, that require precise and clean cuts.

Aerospace Industry: The Ultra High Strength Steel (Aluminum) Automatic Cold Cutting Production Line finds applications in the aerospace industry for the post-processing of materials used in the manufacturing of aircraft components. It ensures high precision and efficiency, meeting the industry's stringent standards.

Construction Sector: Manufacturers in the construction sector can benefit from this production line for the post-processing of high-strength steel or aluminum materials used in structural elements. It enables accurate cutting and shaping of materials, improving the overall quality and efficiency of construction projects.

Industrial Manufacturing: This production line serves the needs of various industrial manufacturing sectors that rely on high-strength steel or aluminum materials for their products. It provides a reliable and efficient solution for post-processing, allowing manufacturers to meet the demands of their customer base.

In conclusion, the Ultra High Strength Steel (Aluminum) Automatic Cold Cutting Production Line offers a fully automated and efficient solution for the post-processing of high-strength steel or aluminum materials. With its precision cutting devices, robotic arms, and automatic loading and unloading system, it ensures high precision, enhanced productivity, and cost-effective manufacturing. This production line finds applications in the automotive, aerospace, construction, and industrial manufacturing sectors, contributing to the production of high-quality and precise components.