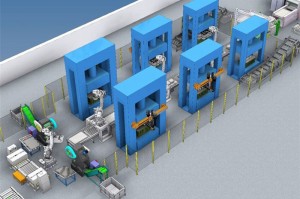

Single-action Sheet metal Stamping Hydraulic Press

Key Advantages

Versatile Capability: With the ability to perform multiple processes, our hydraulic press offers flexibility for sheet metal manipulation. It can stretch, cut, bend, and flange metal sheets, catering to a wide range of production needs.

Independent Systems: The press is equipped with separate hydraulic and electrical systems, ensuring efficient and reliable operation. This independence allows for easy maintenance and troubleshooting when necessary.

Multiple Operating Modes: Our hydraulic press provides two operating modes: continuous cycle (semi-automatic) and manual adjustment, providing options for different production requirements.

Automatic Pressure and Stroke Selection: For each working mode, the press automatically selects between constant pressure and stroke options. This feature ensures optimal precision and efficiency in the production process.

Wide Range of Applications: The press finds extensive use in the automotive industry for the production of thin sheet metal stamping components. Additionally, it is well-suited for applications in aerospace, rail transportation, agricultural machinery, and household appliances.

Product Applications

Our Single-action Sheet Stamping Hydraulic Press is commonly used in various industries for the following applications:

Automotive Industry: Ideal for the manufacturing of automotive thin sheet metal stamping components including body panels, brackets, and structural parts.

Aerospace and Aviation: Well-suited for the production of sheet metal parts used in aircraft and space vehicles, such as fuselage panels, wing components, and engine brackets.

Rail Transportation: Used in the fabrication of sheet metal parts for railcars, locomotives, and railway infrastructure.

Agricultural Machinery: Suitable for the manufacturing of components for agricultural equipment, such as harvesters, tractors, and tillage machines.

Household Appliances: Applied in the production of sheet metal parts for household appliances like refrigerators, washing machines, and air conditioners.

Conclusion: Our Single-action Sheet Stamping Hydraulic Press offers versatility, reliability, and precision for a wide range of sheet metal stamping applications. With its various processes available, independent systems, multiple operating modes, and automatic pressure and stroke selection, it is an excellent choice for efficient and high-quality production. Whether in the automotive industry, aerospace, rail transportation, agriculture, or household appliances, our hydraulic press delivers outstanding performance and contributes to the success of your manufacturing processes. Invest in our press to unlock the potential for streamlined operations and increased productivity.