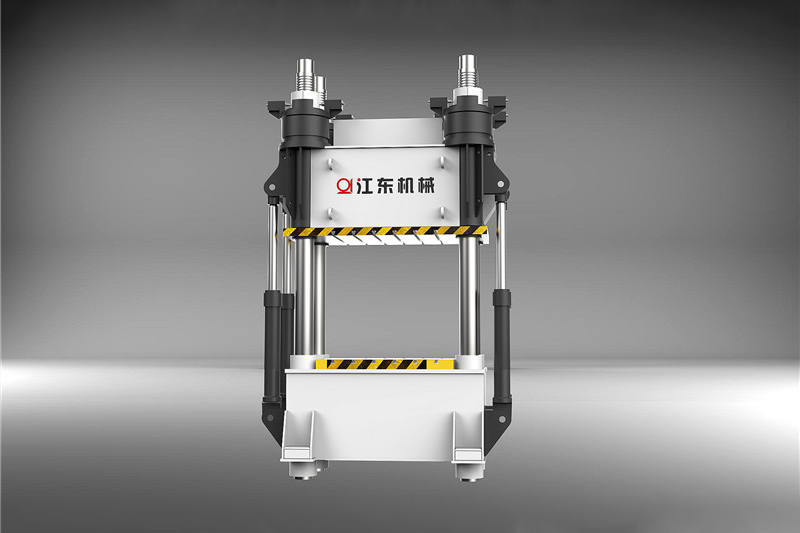

Short stroke composite hydraulic press

Product Advantages

Double-Beam Structure: Our hydraulic press adopts a double-beam structure, offering enhanced stability and precision compared to traditional three-beam presses. This design improves the overall efficiency and accuracy of the forming process, ensuring consistent results and reducing material waste.

Reduced Machine Height: By replacing the traditional three-beam structure, our hydraulic press reduces machine height by 25%-35%. This compact design saves valuable floor space while still delivering the necessary force and stroke length required for composite material forming.

Efficient Stroke Range: The hydraulic press features a cylinder stroke range of 50-120mm. This versatile range satisfies the forming requirements of various composite materials, including those used in processes such as HP-RTM, SMC, LFT-D, GMT, and others. The ability to adjust the stroke length allows for precise control of the molding process, ensuring high-quality, defect-free products.

Advanced Control System: Our hydraulic press is equipped with a touch screen interface and PLC control system. This intuitive setup provides convenient control over parameters such as pressure sensing and displacement sensing. With these features, operators can easily monitor and adjust the forming process to meet specific product requirements, enhancing overall productivity.

Optional Accessories: To further enhance the functionality and automation of our hydraulic press, we offer optional accessories such as a vacuum system, mold change carts, and electronic control communication interfaces. The vacuum system ensures the efficient removal of air and impurities during the forming process, resulting in improved product quality. Mold change carts facilitate quick and effortless mold changes, reducing downtime and increasing overall production efficiency. The electronic control communication interfaces enable seamless integration of the hydraulic press with production lines, allowing for automated control and monitoring.

Product Applications

Aerospace Industry: Our Short Stroke Hydraulic Press finds wide application in the aerospace industry for manufacturing lightweight fiber-reinforced composite products. The precise control over the molding process and the ability to work with various composite materials makes it an ideal solution for producing components used in aerospace applications. These components include aircraft interior panels, wing structures, and other lightweight parts that require high strength and durability.

Automotive Industry: With the growing demand for lightweight and fuel-efficient vehicles, our hydraulic press is crucial in the production of fiber-reinforced composite products used in automotive applications. It enables the efficient forming of components such as body panels, structural reinforcements, and interior parts. The precise stroke control and advanced control system guarantee the consistent quality required by automotive manufacturers.

General Manufacturing: Our hydraulic press is versatile enough to cater to various industries beyond aerospace and automotive. It can be used in the production of composite materials for applications such as sporting goods, construction materials, and consumer products. Its flexibility, accuracy, and efficiency make it an indispensable tool in any manufacturing setting where composite material forming is required.

In conclusion, our Short Stroke Hydraulic Press offers enhanced efficiency and precision in the forming of composite materials. With its double-beam structure, reduced machine height, versatile stroke range, and advanced control system, it provides manufacturers with a reliable and efficient solution for producing high-quality composite products. Whether in the aerospace, automotive, or general manufacturing industries, our hydraulic press delivers the necessary precision and productivity for a wide range of applications.