-

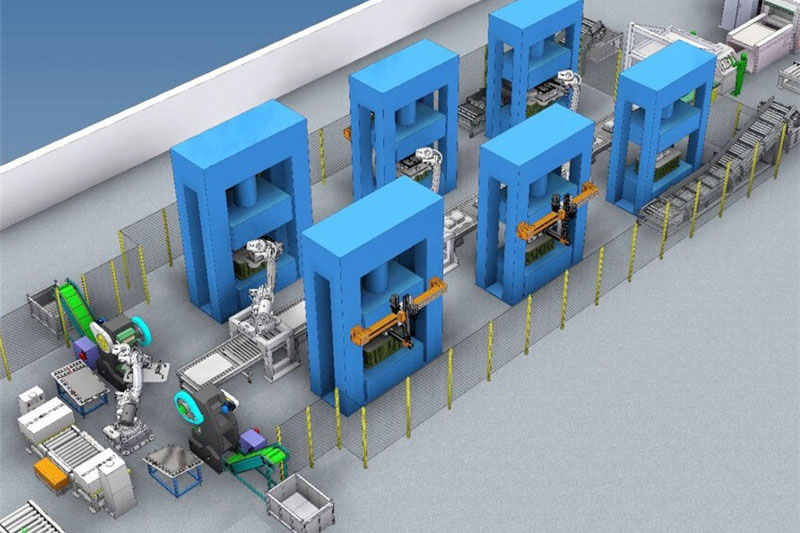

stainless steel water sink production line

The stainless steel water sink production line is an automated manufacturing line that includes processes such as steel coil unwinding, cutting, and stamping to shape the sinks. This production line utilizes robots to replace manual labor, allowing for the automatic completion of sink manufacturing.

The stainless steel water sink production line consists of two main parts: the material supply unit and the sink stamping unit. These two parts are connected by a logistics transfer unit, which facilitates the transportation of materials between them. The material supply unit includes equipment such as coil unwinders, film laminators, flatteners, cutters, and stackers. The logistics transfer unit consists of transfer carts, material stacking lines, and empty pallet storage lines. The stamping unit comprises four processes: angle cutting, primary stretching, secondary stretching, edge trimming, which involve the use of hydraulic presses and robot automation.

The production capacity of this line is 2 pieces per minute, with an annual output of approximately 230,000 pieces.

-

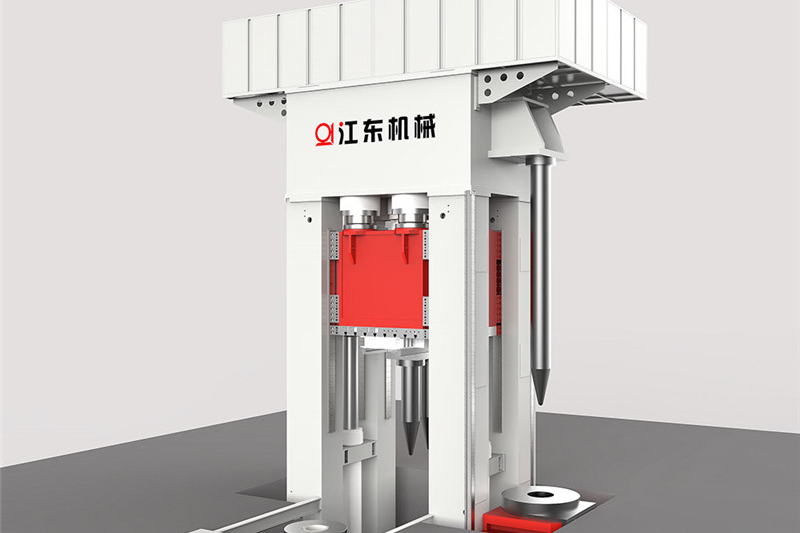

SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

To ensure precise control during the molding process, the hydraulic press is equipped with an advanced servo hydraulic control system. This system enhances position control, speed control, micro opening speed control, and pressure parameter accuracy. The pressure control accuracy can reach up to ±0.1MPa. Parameters such as slide position, downward speed, pre-press speed, micro opening speed, return speed, and exhaust frequency can be set and adjusted within a certain range on the touch screen. The control system is energy-saving, with low noise and minimal hydraulic impact, providing high stability.

To address technical issues such as unbalanced loads caused by asymmetric molded parts and thickness deviations in large flat thin products, or to meet process requirements such as in-mold coating and parallel demolding, the hydraulic press can be equipped with a dynamic instantaneous four-corner leveling device. This device utilizes high-precision displacement sensors and high-frequency response servo valves to control the synchronous correction action of the four-cylinder actuators. It achieves a maximum four-corner leveling accuracy of up to 0.05mm on the entire table.

-

LFT-D long fiber reinforced thermoplastic compression direct molding production line

The LFT-D long fiber reinforced thermoplastic compression direct molding production line is a comprehensive solution for efficiently forming high-quality composite materials. This production line consists of a glass fiber yarn guiding system, a twin-screw glass fiber plastic mixing extruder, a block heating conveyor, a robotic material handling system, a fast hydraulic press, and a centralized control unit.

The production process begins with continuous glass fiber feeding into the extruder, where it is cut and extruded into pellet form. The pellets are then heated and quickly molded into the desired shape using the robotic material handling system and the fast hydraulic press. With an annual production capacity of 300,000 to 400,000 strokes, this production line ensures high productivity.

-

The Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) equipment

The Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) equipment is a cutting-edge solution developed in-house for the production of high-quality carbon fiber components. This comprehensive production line comprises optional preforming systems, an HP-RTM specialized press, an HP-RTM high-pressure resin injection system, robotics, a production line control center, and an optional machining center. The HP-RTM high-pressure resin injection system consists of a metering system, vacuum system, temperature control system, and raw material transportation and storage system. It utilizes a high-pressure, reactive injection method with three-component materials. The specialized press is equipped with a four-corner leveling system, offering an impressive leveling accuracy of 0.05mm. It also features micro-opening capabilities, allowing for rapid production cycles of 3-5 minutes. This equipment enables the batch production and customized flexible processing of carbon fiber components.

-

Metal extrusion/hot die forging hydraulic press

The Metal extrusion/hot die forging hydraulic press is an advanced manufacturing technology for high-quality, efficient, and low-consumption processing of metal components with minimal or no cutting chips. It has gained wide application in various manufacturing industries such as automotive, machinery, light industry, aerospace, defense, and electrical equipment.

The Metal extrusion/hot die forging hydraulic press is specifically designed for the cold extrusion, warm extrusion, warm forging, and hot die forging forming processes, as well as precision finishing of metal components.

-

titanium alloy superplastic forming hydraulic press

The Superplastic Forming Hydraulic press is a specialized machine designed for the near-net forming of complex components made from difficult-to-form materials with narrow deformation temperature ranges and high deformation resistance. It finds widespread application in industries such as aerospace, aviation, military, defense, and high-speed rail.

This hydraulic press utilizes the superplasticity of materials, such as titanium alloys, aluminum alloys, magnesium alloys, and high-temperature alloys, by adjusting the grain size of the raw material to a superplastic state. By applying ultra-low pressure and controlled speeds, the press achieves superplastic deformation of the material. This revolutionary manufacturing process enables the production of components using significantly smaller loads compared to conventional forming techniques.

-

Free forging hydraulic press

The Free Forging Hydraulic Press is a specialized machine designed for large-scale free forging operations. It enables the completion of various forging processes such as elongation, upsetting, punching, expanding, bar drawing, twisting, bending, shifting, and chopping for the production of shafts, rods, plates, discs, rings, and components composed of circular and square shapes. Equipped with complementary auxiliary devices such as forging machinery, material handling systems, rotary material tables, anvils, and lifting mechanisms, the press seamlessly integrates with these components to complete the forging process. It finds wide applications in industries such as aerospace and aviation, shipbuilding, power generation, nuclear power, metallurgy, and petrochemicals.

-

Light Alloy Liquid Die Forging/semisolid forming Production Line

The Light Alloy Liquid Die Forging Production Line is a state-of-the-art technology that combines the advantages of casting and forging processes to achieve near-net shape forming. This innovative production line offers several benefits, including a short process flow, environmental friendliness, low energy consumption, uniform part structure, and high mechanical performance. It consists of a multifunctional CNC liquid die forging hydraulic press, an aluminum liquid quantitative pouring system, a robot, and a bus integrated system. The production line is characterized by its CNC control, intelligent features, and flexibility.

-

Vertical Gas Cylinder/Bullet Housing Drawing Production Line

The Vertical Gas Cylinder/Bullet Housing Drawing Production Line is specifically designed for the production of cup-shaped (barrel-shaped) parts with a thick bottom end, such as various containers, gas cylinders, and bullet housings. This production line enables three essential processes: upsetting, punching, and drawing. It includes equipment such as a feeding machine, medium-frequency heating furnace, conveyor belt, feeding robot/mechanical hand, upsetting and punching hydraulic press, dual-station slide table, transfer robot/mechanical hand, drawing hydraulic press, and material transfer system.

-

Gas Cylinder Horizontal Drawing Production Line

The gas cylinder horizontal drawing production line is designed for the stretching forming process of super-long gas cylinders. It adopts a horizontal stretching forming technique, consisting of the line head unit, material loading robot, long-stroke horizontal press, material-retreating mechanism, and line tail unit. This production line offers several advantages such as easy operation, high forming speed, long stretching stroke, and a high level of automation.

-

Gantry Straightening Hydraulic Press for Plates

Our gantry straightening hydraulic press is designed specifically for the straightening and forming processes of steel plates in industries such as aerospace, shipbuilding, and metallurgy. The equipment consists of a movable cylinder head, a mobile gantry frame, and a fixed worktable. With the ability to perform horizontal displacement on both the cylinder head and the gantry frame along the length of the worktable, our gantry straightening hydraulic press ensures precise and thorough plate correction without any blind spots. The main cylinder of the press is equipped with a micro-movement downward function, allowing for accurate plate straightening. Additionally, the worktable is designed with multiple lifting cylinders in the effective plate area, which facilitates the insertion of correction blocks at specific points and also assists in lifting the plates.ifting of the plate.

-

Automatic Gantry Straightening Hydraulic Press for Bar Stock

Our automatic gantry straightening hydraulic press is a complete production line designed to efficiently straighten and correct metal bar stock. It consists of a mobile hydraulic straightening unit, a detection control system (including workpiece straightness detection, workpiece angle rotation detection, straightening point distance detection, and straightening displacement detection), a hydraulic control system, and an electrical control system. This versatile hydraulic press is capable of automating the straightening process for metal bar stock, ensuring superior accuracy and efficiency.