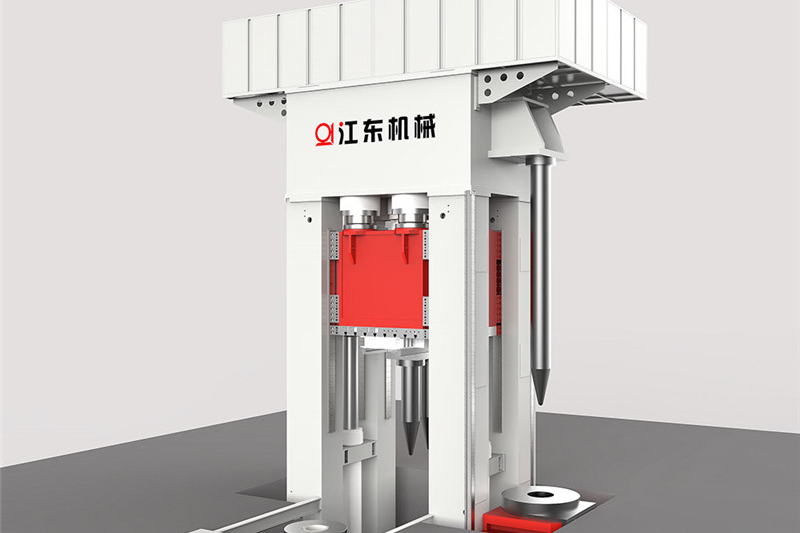

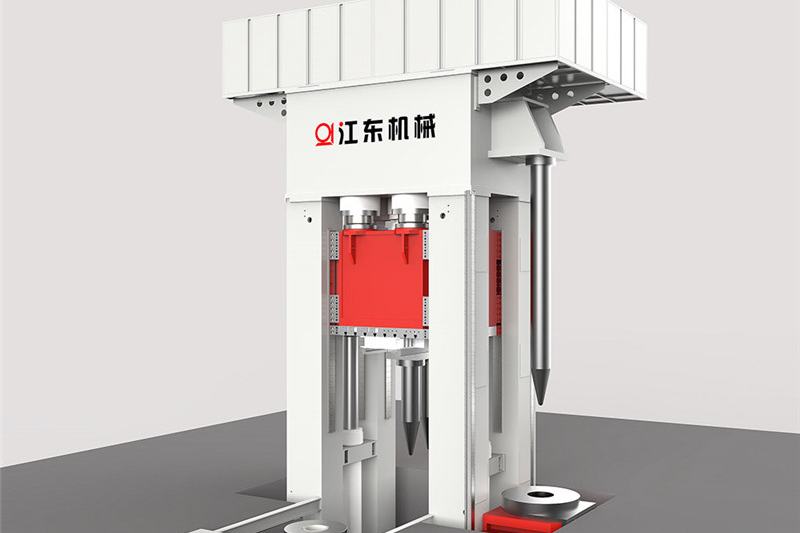

Vertical Gas Cylinder/Bullet Housing Drawing Production Line

Key Features

Versatile Production Capability: The Vertical Gas Cylinder/Bullet Housing Drawing Production Line is suitable for manufacturing a variety of cup-shaped parts with a thick bottom end. It offers flexibility in terms of part dimensions, material choices, and production volumes, catering to different customer requirements.

Efficient Process Flow: With its integrated workflow, this production line minimizes handling and intermediate operations, resulting in a streamlined and efficient manufacturing process. The automated equipment, such as feeding robots and hydraulic presses, ensures high productivity and reduces labor costs.

Precise and Consistent Forming: The production line utilizes advanced hydraulic presses, which provide precise and consistent forming of cup-shaped parts. The upsetting, punching, and drawing processes are carefully controlled to achieve optimal dimensions, surface quality, and structural integrity.

High-Quality End Products: The Vertical Gas Cylinder/Bullet Housing Drawing Production Line guarantees the production of high-quality cup-shaped parts. The thick bottom end ensures robustness and stability, while the precise forming process results in parts with excellent dimensional accuracy and mechanical properties.

Automation and Robotics: The use of feeding robots/mechanical hands and transfer robots/mechanical hands in the production line contributes to increased automation and efficiency. These robots handle the feeding, transfer, and positioning of the workpieces, reducing human intervention and minimizing the risk of errors.

Advanced Heating Technology: The medium-frequency heating furnace incorporated into the production line ensures precise and uniform heating of the workpieces. This technology promotes energy efficiency, reduces heating time, and enhances the overall quality of the formed parts.

Applications

The Vertical Gas Cylinder/Bullet Housing Drawing Production Line finds wide applications in various industries that require cup-shaped parts with a thick bottom end. Some key applications include:

Gas Cylinder Manufacturing: The production line is ideal for producing gas cylinders of different capacities, ensuring reliable and safe storage of gases such as oxygen, nitrogen, and acetylene. The cup-shaped design with a thick bottom end provides structural strength and durability.

Bullet Housing Production: This production line is suitable for manufacturing bullet housings used in firearms and ammunition. The precise forming process ensures proper alignment and dimensions required for accurate bullet seating, contributing to the overall performance and safety of the ammunition.

Container Production: The production line can be used to manufacture a variety of containers, such as storage tanks, drums, and canisters. These containers find application in industries like chemicals, pharmaceuticals, food processing, and transportation.

Industrial Applications: Cup-shaped parts produced by the production line can be used in industrial equipment and machinery, such as pressure vessels, hydraulic cylinders, and power generation components. These parts require excellent structural integrity and dimensional accuracy to ensure safe and efficient operation.

In conclusion, the Vertical Gas Cylinder/Bullet Housing Drawing Production Line offers a versatile and efficient solution for the manufacturing of cup-shaped parts with a thick bottom end. With its precise forming processes, automation capabilities, and applications in various industries, this production line meets the demands for high-quality, cost-effective, and reliable component production.