Die Spotting Hydraulic Press for Precision Mold Adjustment

Key Advantages

Superior Precision: With stroke adjustment capabilities ranging from 0.02mm to 0.05mm per movement, the Die Spotting Hydraulic Press ensures exceptional precision during mold alignment and adjustment. Its fine-tuning options enable operators to achieve accurate and reproducible results, guaranteeing the dimensional accuracy and quality of finished products.

Versatile Adjustment Modes: The hydraulic press offers three different stroke adjustment modes: mechanical four-point adjustment, hydraulic servo adjustment, and pressure-less downward movement. This versatility allows operators to choose the most suitable adjustment method for their specific mold types and spotting processes, ensuring optimal results and efficient operations.

Enhanced Efficiency: By incorporating advanced stroke adjustment capabilities, the hydraulic press significantly reduces the time and effort required for mold alignment and fine-tuning. Operators can swiftly and accurately adjust the stroke, speeding up the mold spotting process, and improving overall efficiency in mold manufacturing and repair.

Improved Mold Quality: The precise stroke control offered by the hydraulic press ensures proper mold alignment, enabling effective mold debugging and accurate adjustments. This results in improved mold quality, reducing the risk of defects and ensuring the production of high-quality parts.

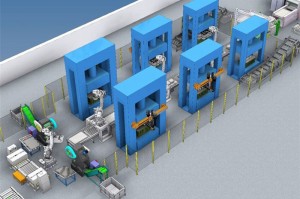

Wide Range of Applications: The Die Spotting Hydraulic Press is widely used in the manufacturing and repair of medium to large-scale stamping molds. It is suitable for various industries that require precision mold adjustment, such as automotive, aerospace, and general manufacturing. It can be used for aligning and debugging molds for automotive body parts, structural components, electronic enclosures, and various other stamped products.

Product Applications

The Die Spotting Hydraulic Press is designed for mold processing and alignment in various industries. Some common applications include:

Automotive Industry: The hydraulic press is used for precise mold alignment and adjustment in the manufacturing of automotive body panels, chassis components, brackets, and other structural parts.

Aerospace Industry: It facilitates accurate mold debugging and alignment for aerospace components, such as fuselage parts, wing structures, and interior components.

General Manufacturing: The hydraulic press is utilized in the production and repair of molds for various products, including electronic enclosures, appliances, and consumer goods.

Mold Repair and Maintenance: It is an essential tool for mold repair and maintenance workshops, providing efficient mold alignment and precise adjustments to restore molds to their optimal condition.

In conclusion, the Die Spotting Hydraulic Press offers superior precision, versatile adjustment modes, enhanced efficiency, and improved mold quality. Its broad range of applications makes it a valuable asset in industries that require precision mold processing and adjustment. Invest in this advanced hydraulic press to optimize mold debugging, improve production efficiency, and ensure the production of high-quality stamped products.