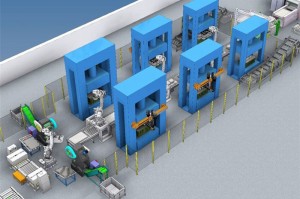

Fully Automated Sheet metal Stamping Hydraulic Press Production Line for automotive

Key Features

Robotic Arm Material Handling: The integration of robotic arms in the production line enables precise and efficient material handling, eliminating the need for manual labor. This reduces human errors, enhances safety, and increases overall productivity.

Automated Detection System: The production line includes an advanced detection system that ensures high-quality output. This system detects any defects or irregularities in the materials, allowing for immediate corrective actions and reducing waste.

Die Quick-Change System: With a quick-change system integrated, the production line enables rapid tooling changes, minimizing downtime and improving overall efficiency. This feature provides flexibility for different stamping needs and enhances production flexibility.

Waste Material Management: The production line features a waste material line that efficiently collects and disposes of scrap or waste materials. This ensures a clean and organized workplace, reducing the risk of accidents and improving operational efficiency.

Product Benefits

Enhanced Efficiency: The fully automated nature of this production line eliminates the need for manual intervention, significantly reducing production time and labor costs. It ensures continuous operation, resulting in higher output and improved overall efficiency.

Increased Precision: The robotic arm material handling ensures precise and repeatable positioning of the materials, resulting in accurate stamping and reducing material waste. The automated detection system further enhances precision by identifying any defects or irregularities, improving the quality of the final products.

Improved Safety: With the integration of robotic arms for material handling, human involvement is minimized, reducing the risk of accidents. This enhances the safety of the production line and provides a safer work environment for the operators.

Applications: The Fully Automated Automotive Thin Sheet Stamping Hydraulic Press Production Line is suitable for various automotive stamping applications. It can be used for manufacturing automotive body panels, structural components, brackets, and other sheet metal parts required in the automotive industry.

Product Applications

Automotive Industry: This production line caters to the needs of the automotive industry by automating the stamping process for thin sheet materials. It is suitable for producing various automotive components, such as doors, hoods, fenders, and roof panels.

Manufacturing Sector: Manufacturers in various industries that require precise and automated stamping processes can benefit from this production line. It can be utilized in producing electrical enclosures, consumer appliances, and other products made from thin sheet materials.

Sheet Metal Fabrication: The Fully Automated Automotive Thin Sheet Stamping Hydraulic Press Production Line offers a reliable solution for sheet metal fabrication companies. It enables efficient and precise stamping of thin sheet materials, enhancing the overall productivity and quality of the fabricated products.

Stamping Service Providers: Companies specializing in providing stamping services can utilize this production line to improve their competitiveness in the market. The automation and intelligent features of the line contribute to faster turnaround times, higher quality output, and increased customer satisfaction.

In conclusion, the Fully Automated Automotive Thin Sheet Stamping Hydraulic Press Production Line brings automation, precision, and efficiency to the stamping process for thin sheet materials. With its robotic arm material handling, automated detection system, and quick-change capabilities, it enhances productivity, reduces waste, and ensures high-quality output. This production line finds applications in the automotive industry, various manufacturing sectors, sheet metal fabrication, and stamping service providers.